- TEL:0086[22]28571008

- FAX:

- CEL:WhatsApp +86 18322353397

0086 13602021719 - E-MAIL:info@broater.com & bendamold@163.com

- ADD:No.7 Fagang road,Shuanggang Industrial Zone,jinnan,Tianjin,China.(300350)

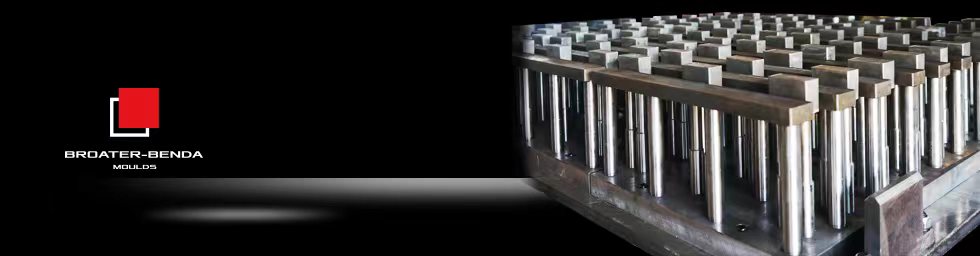

Broater-benda workshop comes up with clever tricks

Recently, there has been progress in the rationalization proposal activity of the Broater-benda mold workshop, and some small tricks can quickly improve efficiency and reliability. The use of a new type of special torque wrench instead of a regular digital torque wrench can provide early warning and determine whether it is suitable, avoiding bolt detachment or overload caused by insufficient or excessive force, effectively improving assembly efficiency and reliability. The company has praised and rewarded such suggestions, encouraging everyone to continue implementing them.